مطحنة قطع عالية السرعةZERMA

GST 250/600

مطحنة قطع عالية السرعة

ZERMA

GST 250/600

السعر الافتتاحي دون ضريبة القيمة المضافة

١٩٬٤٠٠ €

سنة الصنع

٢٠٢٥

الحالة

جديد

الموقع

Buchholz in der Nordheide

عرض الصور

عرض الخريطة

بيانات عن الآلة

السعر والموقع

السعر الافتتاحي دون ضريبة القيمة المضافة

١٩٬٤٠٠ €

- الموقع:

- Vaenser Weg 12, 21244 Buchholz in der Nordheide, Deutschland

اتصل

تفاصيل العرض

- معرّف القائمة:

- A13548352

- التحديث الأخير:

- في ٠٣.٠٥.٢٠٢٥

الوصف

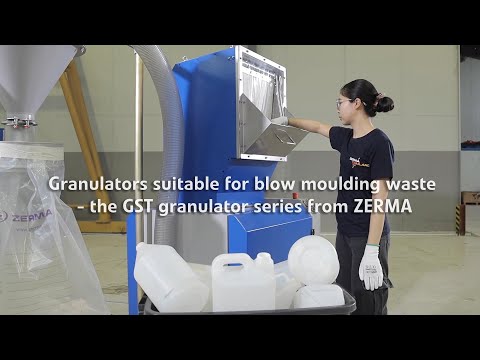

Size reduction of large-volume blow molded parts as well as start and end pieces

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with special emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths from 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material jams. As with all ZERMA granulators, the rotor and stator knives are adjustable outside the machine, reducing downtime for maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material pickup and minimizes the risk of jams.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling e.g. voluminous parts such as bottles, canisters, crates. Due to the low feeding height, the machines can be easily fed with material by hand or by a small conveyor belt. The low noise emission and the small footprint make the granulator a perfect solution for inline size reduction

Optional rear panel with higher stator knife M version:

The feed method with a higher positioned stator knife is better suited for thicker walled and more compact parts, such as injection molded parts, profiles, plates, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high quality regrind is obtained regardless of the material type or shape, such as injection molded parts, profiles, plates, etc.

Control system and control panel:

The integrated control system and control panel not only comply with all applicable safety regulations, but can also be customized to meet specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available that reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 er cyclone

Rotor diameter (mm) 250

Rotor width (mm) 600

Drive (kW) 11

Iodpfjp Sr Iasx Af Hoht

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 1450

Feed opening (mm) 380 x 600

Feed opening option of M version (mm) 295 x 600

تمت ترجمة الإعلان تلقائياً، وقد تكون هنالك بعض الأخطاء في الترجمة.

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with special emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths from 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material jams. As with all ZERMA granulators, the rotor and stator knives are adjustable outside the machine, reducing downtime for maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material pickup and minimizes the risk of jams.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling e.g. voluminous parts such as bottles, canisters, crates. Due to the low feeding height, the machines can be easily fed with material by hand or by a small conveyor belt. The low noise emission and the small footprint make the granulator a perfect solution for inline size reduction

Optional rear panel with higher stator knife M version:

The feed method with a higher positioned stator knife is better suited for thicker walled and more compact parts, such as injection molded parts, profiles, plates, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high quality regrind is obtained regardless of the material type or shape, such as injection molded parts, profiles, plates, etc.

Control system and control panel:

The integrated control system and control panel not only comply with all applicable safety regulations, but can also be customized to meet specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available that reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 er cyclone

Rotor diameter (mm) 250

Rotor width (mm) 600

Drive (kW) 11

Iodpfjp Sr Iasx Af Hoht

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 1450

Feed opening (mm) 380 x 600

Feed opening option of M version (mm) 295 x 600

تمت ترجمة الإعلان تلقائياً، وقد تكون هنالك بعض الأخطاء في الترجمة.

مورد

ملاحظة: سجّل مجانًا أو سجّل الدخول، للاطلاع على جميع المعلومات.

مسجل منذ: 2023

تقديم الطلب

الهاتف & فاكس

+49 4181 ... إعلانات

قد تهمك أيضًا هذه الإعلانات.

إعلان صغير

Kassel

Kassel

٣٬٢٦٤ km

مسلفات أخرى

AmazoneCatros+ 3003

AmazoneCatros+ 3003

إعلان صغير

Dinkelscherben

Dinkelscherben

٢٬٩٦٣ km

حزام ناقل حزام سير محطم

die magnetprofis2019020502

die magnetprofis2019020502

إعلان صغير

Deitingen

Deitingen

٣٬٠٤٢ km

أداة آلة طحن

W. ScherrerSB 10

W. ScherrerSB 10

إعلان صغير

Wasbek

Wasbek

٣٬٤٨٢ km

آلة الحفر العمودية وآلة الحفر الرأسية - SSB F 60 Super VT PRO

KnuthSSB F 60 Super VT PRO

KnuthSSB F 60 Super VT PRO

إعلان صغير

Mindelheim

Mindelheim

٢٬٩٤٧ km

رأى الفرقة ميتري مزدوج

MIOTALS 255 DG

MIOTALS 255 DG

إعلان صغير

Dortmund

Dortmund

٣٬٣٧٥ km

اضغط الفرامل

LAMI NOVAP 1340

LAMI NOVAP 1340

إعلان صغير

Berlin

Berlin

٣٬١٩٧ km

شاحنة صغيرة

PEUGEOTBoxer Euro 5 3,80m

PEUGEOTBoxer Euro 5 3,80m

إعلان صغير

Zuzenhausen

Zuzenhausen

٣٬١٣٤ km

التقطيع

ZERMAZRS

ZERMAZRS

إعلان صغير

Velbert

Velbert

٣٬٣٨٢ km

نظام الربط

CyklopXZE-311

CyklopXZE-311

إعلان صغير

Sinsheim

Sinsheim

٣٬١٢٣ km

المحبب

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

تم حذف إعلانك بنجاح

حدث خطأ