مكبس بالات بباب ضغط أمامي LP 50 EH1Presona AB

LP 50 EH1

مكبس بالات بباب ضغط أمامي LP 50 EH1

Presona AB

LP 50 EH1

سنة الصنع

٢٠٠٥

الحالة

مستعمل

الموقع

هولندا

عرض الصور

عرض الخريطة

بيانات عن الآلة

- وصف الآلة:

- مكبس بالات بباب ضغط أمامي LP 50 EH1

- المصنّع:

- Presona AB

- الموديل:

- LP 50 EH1

- سنة الصنع:

- ٢٠٠٥

- الحالة:

- تمت صيانته في الورشة (مستعمل)

- الوظائف:

- يعمل بكامل كفاءته

- ساعات التشغيل:

- ٣٠٬٤٠٨ h

السعر والموقع

- الموقع:

- , هولندا

اتصل

تفاصيل فنية

- قوة الضغط:

- ٥٠ t

- عرض فتحة التعبئة:

- ١٬١٠٠ مم

- طول فتحة التعبئة:

- ١٬٢٥٠ مم

- عرض البالة:

- ١٬١٠٠ مم

- ارتفاع البالة:

- ٧٢٠ مم

- وزن البالة:

- ٥٥٠ كجم

- الوزن الإجمالي:

- ١٦٬٠٠٠ كجم

- سعة خزان الزيت:

- ٦٠٠ ل

- سنة آخر إصلاح شامل:

- ٢٠٢٤

تفاصيل العرض

- معرّف القائمة:

- A17766606

- التحديث الأخير:

- في ٢٠.٠٦.٢٠٢٥

الوصف

Technical data baler:

Manufacturer Presona AB

Type LP 50 EH1

Year of construction 2005

Operating hours 30,408 hours, as of April

Number of pressed bales 198,059 as of April

Pressing force main press 50 tonnes

Specific pressing force 63 N/cm²

Theoretical throughput capacity 530 m³/hour

Throughput capacity under operating conditions 260 m³/hour

Dimensions of feed chute 1,250 x 1,100 mm

Bale chamber volume 2.2 m³

Bale dimensions 1,100 x 720 mm, variable length

Drive power 22 kW

Tying 5-fold vertical, fully automatic

Throughput rates with a

bulk density of 30 kg/cbm 6 up to 7 tonnes/hour

Bulk weight of 50 kg/cbm 7 up to 9 tonnes/hour

Bulk weight of 100 kg/cbm 11 up to 14 tonnes/hour

Bale density (paper/newspapers) 400 to 550 kg/m³

Hydraulic oil tank capacity 600 litres

PLC control Telemecanique TSX Micro

Schneider Magelis control panel

Effective transport dimensions excl. baler 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight press approx. 16 tonnes

Condition of the baler:

The machine was partial overhauled in our workshop and general maintenance work was carried out. After completion of the overhaul work, the press was tested during operation and is available for sale at short notice.

The following overhaul work was carried out:

General work:

Machine cleaned, derusted, primed, partially painted

Wire entry marks in the press channel feed-throughs welded shut and smoothed

Hydraulic unit:

Hydraulic oil tank emptied, tank cleaned, new oil filled

Oil filter and air filter replaced

Leaky oil sight glass on hydraulic oil tank replaced

All hydraulic hoses replaced

Electrics:

English language installed in the programme menu

Two key switches in the control panel replaced

Control cabinet replaced

Signal lamp on the control cabinet replaced

Flaps end switch replaced

Electrical system of the turbulator replaced, connected and tested

Press ram:

All four rollers removed from the press ram and replaced

Main hydraulic cylinder dismantled, disassembled and partially overhauled, cylinder tube honed, complete seal set replaced, leak test performed

All plastic wear pads on the press ram replaced

Pre-press:

Both bearings on the pre-press shaft replaced.

Both hydraulic cylinders dismantled, disassembled and partially overhauled, both cylinder tubes honed, complete seal sets replaced, leak test performed.

Scraper flap on the pre-press replaced.

Binding system:

Two complete needles with wire deflection rollers replaced

Needles adjusted and set

All wire deflection rollers in the needle heads replaced

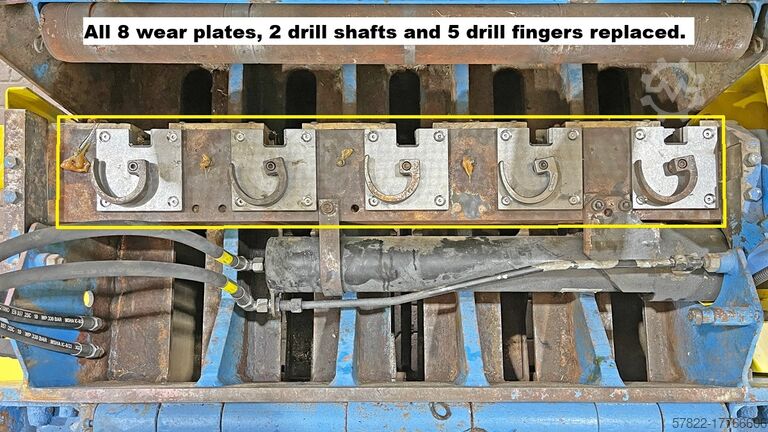

Drill fingers replaced

Kedpfju Thhrox Abgowt

Two drill shafts replaced

All 8 wear plates on the Drillomat, under the drill fingers, replaced

Scope of delivery:

Only the baler will be sold.

The documentation (Manual, CE-declaration, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Manufacturer Presona AB

Type LP 50 EH1

Year of construction 2005

Operating hours 30,408 hours, as of April

Number of pressed bales 198,059 as of April

Pressing force main press 50 tonnes

Specific pressing force 63 N/cm²

Theoretical throughput capacity 530 m³/hour

Throughput capacity under operating conditions 260 m³/hour

Dimensions of feed chute 1,250 x 1,100 mm

Bale chamber volume 2.2 m³

Bale dimensions 1,100 x 720 mm, variable length

Drive power 22 kW

Tying 5-fold vertical, fully automatic

Throughput rates with a

bulk density of 30 kg/cbm 6 up to 7 tonnes/hour

Bulk weight of 50 kg/cbm 7 up to 9 tonnes/hour

Bulk weight of 100 kg/cbm 11 up to 14 tonnes/hour

Bale density (paper/newspapers) 400 to 550 kg/m³

Hydraulic oil tank capacity 600 litres

PLC control Telemecanique TSX Micro

Schneider Magelis control panel

Effective transport dimensions excl. baler 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight press approx. 16 tonnes

Condition of the baler:

The machine was partial overhauled in our workshop and general maintenance work was carried out. After completion of the overhaul work, the press was tested during operation and is available for sale at short notice.

The following overhaul work was carried out:

General work:

Machine cleaned, derusted, primed, partially painted

Wire entry marks in the press channel feed-throughs welded shut and smoothed

Hydraulic unit:

Hydraulic oil tank emptied, tank cleaned, new oil filled

Oil filter and air filter replaced

Leaky oil sight glass on hydraulic oil tank replaced

All hydraulic hoses replaced

Electrics:

English language installed in the programme menu

Two key switches in the control panel replaced

Control cabinet replaced

Signal lamp on the control cabinet replaced

Flaps end switch replaced

Electrical system of the turbulator replaced, connected and tested

Press ram:

All four rollers removed from the press ram and replaced

Main hydraulic cylinder dismantled, disassembled and partially overhauled, cylinder tube honed, complete seal set replaced, leak test performed

All plastic wear pads on the press ram replaced

Pre-press:

Both bearings on the pre-press shaft replaced.

Both hydraulic cylinders dismantled, disassembled and partially overhauled, both cylinder tubes honed, complete seal sets replaced, leak test performed.

Scraper flap on the pre-press replaced.

Binding system:

Two complete needles with wire deflection rollers replaced

Needles adjusted and set

All wire deflection rollers in the needle heads replaced

Drill fingers replaced

Kedpfju Thhrox Abgowt

Two drill shafts replaced

All 8 wear plates on the Drillomat, under the drill fingers, replaced

Scope of delivery:

Only the baler will be sold.

The documentation (Manual, CE-declaration, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

مستندات

مورد

ملاحظة: سجّل مجانًا أو سجّل الدخول، للاطلاع على جميع المعلومات.

مسجل منذ: 2017

تقديم الطلب

الهاتف & فاكس

+31 597 2... إعلانات

قد تهمك أيضًا هذه الإعلانات.

إعلان صغير

ألمانيا

ألمانيا

٣٬١٤٥ km

Baler

DIXI40 SLK

DIXI40 SLK

إعلان صغير

هولندا

هولندا

٣٬٥٣٦ km

مكبس ذو رباط متقاطع 8 أضعاف

Presona ABLP 80 VHK 1

Presona ABLP 80 VHK 1

إعلان صغير

Kaufungen

Kaufungen

٣٬٢٥٦ km

وحدة جرار قياسية

MERCEDES-BENZActros 1845 SZM 4x2 Streamspace *Retarder

MERCEDES-BENZActros 1845 SZM 4x2 Streamspace *Retarder

إعلان صغير

Blachownia

Blachownia

٢٬٨٥٠ km

الصحافة الورقية

American Baler COhydrauliczna

American Baler COhydrauliczna

إعلان صغير

Wuppertal

Wuppertal

٣٬٣٧٣ km

آلة إعادة التدوير - مصنع التحبيب / الشلال

AGRIFONAM-145

AGRIFONAM-145

إعلان صغير

Tata

Tata

٢٬٥٦١ km

مكبس قنوات Pal Pacomat V 50t

PAAL PACOMAT V50ton 500kg bale

PAAL PACOMAT V50ton 500kg bale

إعلان صغير

Karlholmsbruk

Karlholmsbruk

٣٬٨٨٢ km

شيبير

Söderhamn Eriksson670-56

Söderhamn Eriksson670-56

إعلان صغير

Lagedi

Lagedi

٣٬٦٥٥ km

حاوية الضغط

HusmannSPB 20 SEN-E

HusmannSPB 20 SEN-E

إعلان صغير

Fohnsdorf

Fohnsdorf

٢٬٦٧١ km

الصحافة الخردة

ATM Recyclingsystems GmbHPaketierpresse SP 100 AK-2

ATM Recyclingsystems GmbHPaketierpresse SP 100 AK-2

إعلان صغير

Lagedi

Lagedi

٣٬٦٥٥ km

حاوية الصحافة قرطاسية

HusmannSI- SEL- V2

HusmannSI- SEL- V2

تم حذف إعلانك بنجاح

حدث خطأ