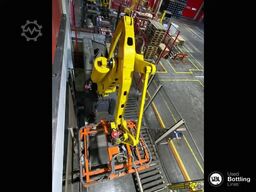

جهاز نزع الأكياسFANUC

M-410 iB 160

جهاز نزع الأكياس

FANUC

M-410 iB 160

سنة الصنع

٢٠٠٣

الحالة

مستعمل

الموقع

Fumane (Verona)

عرض الصور

عرض الخريطة

بيانات عن الآلة

- وصف الآلة:

- جهاز نزع الأكياس

- المصنّع:

- FANUC

- الموديل:

- M-410 iB 160

- سنة الصنع:

- ٢٠٠٣

- الحالة:

- مستعمل

- ساعات التشغيل:

- ١٠٬٠٠٠ h

السعر والموقع

- موقع البائع:

- Via Incisa 1, 37022 Fumane (Verona), إيطاليا

اتصل

تفاصيل العرض

- معرّف القائمة:

- A18007671

- الرقم المرجعي:

- DEPAL31

- التحديث الأخير:

- في ١٦.١٢.٢٠٢٤

الوصف

Used Robot Depalletizer Fanuc 2003 – The Ultimate Solution for Depalletizing Operations

Are you looking for a reliable and efficient robot depalletizer for your business operations? Look no further than the 2003 Fanuc Robot Depalletizer model M-410 iB 160. Equipped with a pick-up head for cardboard and an available base, this depalletizer is designed specifically for depalletizing tasks.

With its intelligent cable routing inside the hollow wrist, high operating speeds, and high inertia and wrist moments, this machine can handle large grippers and heavy payloads with ease. Its 6-axis control servo gripper provides better adaptability in handling products of different sizes.

Operating within an optimized workspace and with high vertical travel, this robot can depalletize products up to a height of almost 2.7 meters. The integrated base and controller in the pedestal (or the available non-pedestal version) save floor space and simplifies transportation and installation.

Upgrade your depalletizing operations with the 2003 Fanuc Robot Depalletizer – the ultimate solution for efficient and effective depalletizing. With a gripper head for depalletizing one layer of bottles at a time (inflatable)

Botte holding system:

This Fanuc robot depalletizer has a particular bottle gripper:

Use the neck bottle gripping system using inflatable bars.

This system helps to process shaped bottles and therefore allows them to be deposited on the loading table with irregular bottles.

Bedpfxjvgvx De Ah Ijlc

The classic push system has this limitation, it cannot process bottles other than round ones.

But the Fanuc robot depalletizer has a speed of 200 layers per hour to a maximum of 12,000 BPH.

Another important feature is the space required to work with that equipment, compared to traditional systems at least 50% of the usable surface is saved; for the same performance, a robot is always preferable, also because being able to change the bottle gripper, all types of bottles can be processed with very high peak loads.

Are you looking for a reliable and efficient robot depalletizer for your business operations? Look no further than the 2003 Fanuc Robot Depalletizer model M-410 iB 160. Equipped with a pick-up head for cardboard and an available base, this depalletizer is designed specifically for depalletizing tasks.

With its intelligent cable routing inside the hollow wrist, high operating speeds, and high inertia and wrist moments, this machine can handle large grippers and heavy payloads with ease. Its 6-axis control servo gripper provides better adaptability in handling products of different sizes.

Operating within an optimized workspace and with high vertical travel, this robot can depalletize products up to a height of almost 2.7 meters. The integrated base and controller in the pedestal (or the available non-pedestal version) save floor space and simplifies transportation and installation.

Upgrade your depalletizing operations with the 2003 Fanuc Robot Depalletizer – the ultimate solution for efficient and effective depalletizing. With a gripper head for depalletizing one layer of bottles at a time (inflatable)

Botte holding system:

This Fanuc robot depalletizer has a particular bottle gripper:

Use the neck bottle gripping system using inflatable bars.

This system helps to process shaped bottles and therefore allows them to be deposited on the loading table with irregular bottles.

Bedpfxjvgvx De Ah Ijlc

The classic push system has this limitation, it cannot process bottles other than round ones.

But the Fanuc robot depalletizer has a speed of 200 layers per hour to a maximum of 12,000 BPH.

Another important feature is the space required to work with that equipment, compared to traditional systems at least 50% of the usable surface is saved; for the same performance, a robot is always preferable, also because being able to change the bottle gripper, all types of bottles can be processed with very high peak loads.

مورد

ملاحظة: سجّل مجانًا أو سجّل الدخول، للاطلاع على جميع المعلومات.

مسجل منذ: 2021

تقديم الطلب

الهاتف & فاكس

+39 344 0... إعلانات

قد تهمك أيضًا هذه الإعلانات.

إعلان صغير

Fumane (Verona)

Fumane (Verona)

٢٬٧٣١ km

منصة تحميل

FANUCM-410 iB 160

FANUCM-410 iB 160

إعلان صغير

Ystad

Ystad

٣٬٤٦٨ km

مُشكِّل حراري

ILPRATMF SPEEDYFORM

ILPRATMF SPEEDYFORM

إعلان صغير

Braunschweig

Braunschweig

٣٬٣٠٤ km

آلة التغليف بالحرارة / الفقاعة

AUTOVAKM320

AUTOVAKM320

إعلان صغير

Veliko Tarnovo

Veliko Tarnovo

١٬٨٦٩ km

صواني

SEALPAC800

SEALPAC800

إعلان صغير

Urk

Urk

٣٬٥٥٥ km

المشكل الحراري

WebomaticAPS ML 7100

WebomaticAPS ML 7100

إعلان صغير

Krotoszyn

Krotoszyn

٢٬٩٨٩ km

آلة التعبئة والتغليف

MultivacR230

MultivacR230

إعلان صغير

Ukmergė

Ukmergė

٣٬٢٠٢ km

موزع البليت الآلي ، المعبئ

UMP TechnikaPD-10

UMP TechnikaPD-10

إعلان صغير

Romano di Lombardia

Romano di Lombardia

٢٬٧٩٦ km

المطرز

BAITHE VISION 2

BAITHE VISION 2

إعلان صغير

Lipsko

Lipsko

٢٬٧٣٠ km

مُشكِّل حراري

MultivacR140

MultivacR140

إعلان صغير

Misterton

Misterton

٣٬٩٤١ km

حشو الفراغ

RiscoRS1040 MAS

RiscoRS1040 MAS

تم حذف إعلانك بنجاح

حدث خطأ